Our products

Aviocom B.V.

Aviocom BV, a subsidiary of Gaches Chimie, stands out as the premier distributor of Specialty Chemical Compounds, exclusively dedicated to serving the aerospace industry. With a comprehensive portfolio of over 10,000 high-performance products, we are committed to delivering excellence in every facet of our services.

OUR MISSION

Our core mission revolves around enhancing the availability, utilization, and societal acceptance of chemicals. Through close collaboration with our customers, we strive to create solutions that not only cut costs but also enhance performance and promote sustainability.

Reduce cost and focus on your key activities while we seamlessly manage all your chemical requirements and enhance product availability at the same time.

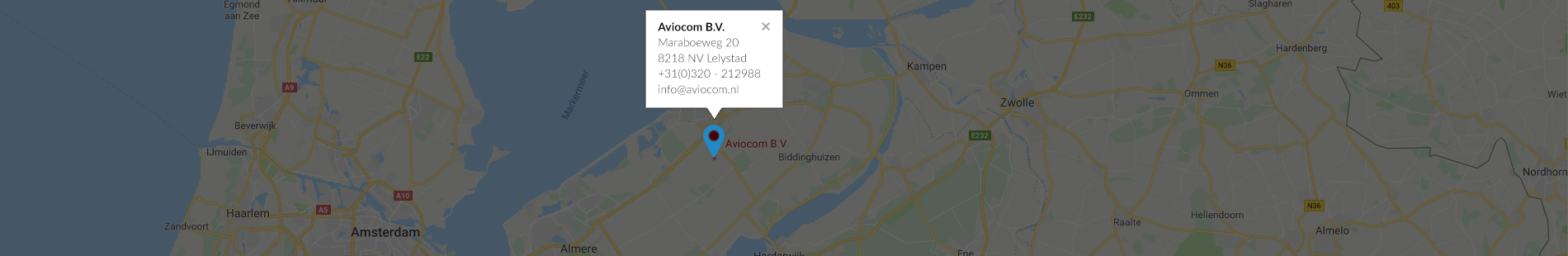

Contact

Providing exceptional customer service lies at the heart of the mission of our organization. Our multi-lingual customer service team is made up of highly skilled professionals with expertise in your industry. please let us know how we can help you by filling out the form.

- Aviocom B.V.

Maraboeweg 20

8218 NV Lelystad - +31(0)320-212988

- info@aviocom.nl